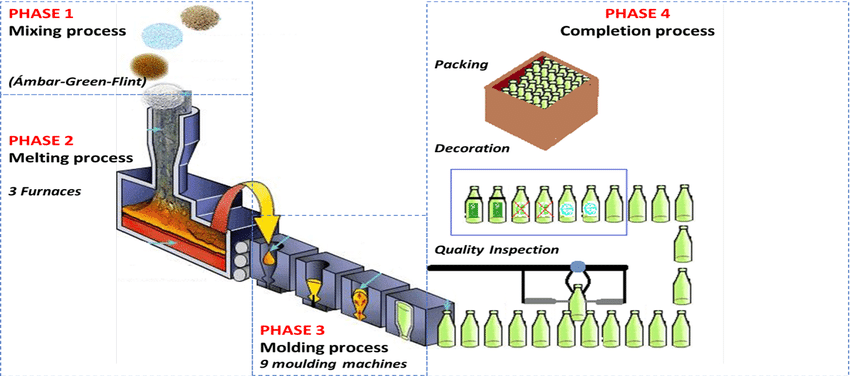

The glass production process includes: batching, melting, forming, annealing and other processes. They are introduced as follows:

- Ingredients: According to the designed ingredient list, weigh various raw materials and mix them evenly in a mixer. The main raw materials of glass are: quartz sand, limestone, feldspar, soda ash, boric acid, etc. 2. Melting, the prepared raw materials are heated to high temperature to form a uniform bubble-free glass liquid. This is a very complex physical and chemical reaction process. Glass is melted in a furnace. There are two main types of melting furnaces: one is a crucible kiln, in which the glass material is contained in the crucible and heated outside the crucible. Small crucible kilns only hold one crucible, while large ones can hold up to 20 crucibles. Crucible kilns are produced in batches. Currently, only optical glass and colored glass are produced using crucible kilns. The other is a pool kiln, in which the glass material is melted in the kiln pool, and an open flame is heated above the glass liquid surface. The melting temperature of glass is mostly between 1300~1600゜C. Most are heated by flames, and a small amount are heated by current, which are called electric melting furnaces. Nowadays, pool kilns are produced continuously. Small pool kilns can be several meters long, and large ones can be as large as more than 400 meters.

- Forming is to transform the molten glass into a solid product with a fixed shape. Forming must be carried out within a certain temperature range. This is a cooling process. The glass first changes from a viscous liquid state to a plastic state, and then to a brittle solid state.

Forming methods can be divided into two categories: artificial forming and mechanical forming.

A. Artificially formed.

(1) Blowing, use a nickel-chromium alloy blowpipe, pick a ball of glass and blow it while turning it in the mold. Mainly used to form glass bubbles, bottles, balls (for marking lenses), etc.

(2) Drawing, after blowing into small bubbles, another worker sticks them with a top plate, and the two people blow and pull them mainly to make glass tubes or rods.

(3) Pressing, pick a ball of glass, cut it with scissors so that it falls into the concave mold, and then press it with the male mold. Mainly used to form cups, plates, etc.

(4) Free forming, after picking the materials, use pliers, scissors, tweezers and other tools to directly make handicrafts.

B. Mechanical forming. Because artificial forming is labor-intensive, high temperature, and poor conditions, most of it has been replaced by mechanical forming, except for free forming. In addition to pressing, blowing and drawing, mechanical forming also includes:

(1) Calendering method, used to produce thick flat glass, patterned glass, wire-clip glass, etc.

(2) Casting method to produce optical glass.

(3) Centrifugal casting method, used to manufacture large-diameter glass tubes, vessels and large-capacity reaction pots. This involves injecting the glass melt into a mold that rotates at high speed. Due to centrifugal force, the glass sticks to the mold wall. The rotation continues until the glass hardens.

(4) Sintering method, used to produce foam glass. It adds a foaming agent to the glass powder and heats it in a covered metal mold. During the heating process, the glass forms many closed bubbles, which is a good thermal insulation and sound insulation material. In addition, the forming of flat glass includes vertical drawing method, flat drawing method and float method. The float method is a method that allows the glass flow to float on the surface of molten metal (tin) to form flat glass. Its main advantages are high glass quality (flat, smooth), fast pulling speed, and large output.

- Annealing: The glass undergoes drastic temperature changes and shape changes during the forming process, which leaves thermal stress in the glass. This thermal stress reduces the strength and thermal stability of the glass article. If it is cooled directly, it is likely to break by itself during the cooling process or during subsequent storage, transportation and use. In order to eliminate the cold explosion phenomenon, glass products must be annealed after forming. Annealing is to maintain or slowly cool down within a certain temperature range for a period of time to eliminate or reduce the thermal stress in the glass to an allowable value.

In addition, some glass products can be stiffened to increase their strength. Including: physical stiffening (quenching), used for thicker glasses, tabletop glass, car windshields, etc.; and chemical stiffening (ion exchange), used for watch cover glass, aviation glass, etc. The principle of stiffening is to generate compressive stress on the surface layer of the glass to increase its strength.